Enhancing Your Car's Efficiency with Import Engines

Enhancing Your Car's Efficiency with Import Engines

Blog Article

Checking Out the Most Current Technological Innovations in Import Engines and Just How They Boost Driving Experience

In the world of auto engineering, the landscape of import engines is undertaking a profound transformation driven by cutting-edge technical innovations. From the development of turbocharged engines to the assimilation of crossbreed technology, the current improvements are reinventing the driving experience in ways formerly unthinkable. As import manufacturers press the borders of efficiency and performance through improved gas shot systems and advanced engine monitoring services, the concern emerges: Exactly how do these advancements truly impact the means we engage with our cars on the road?

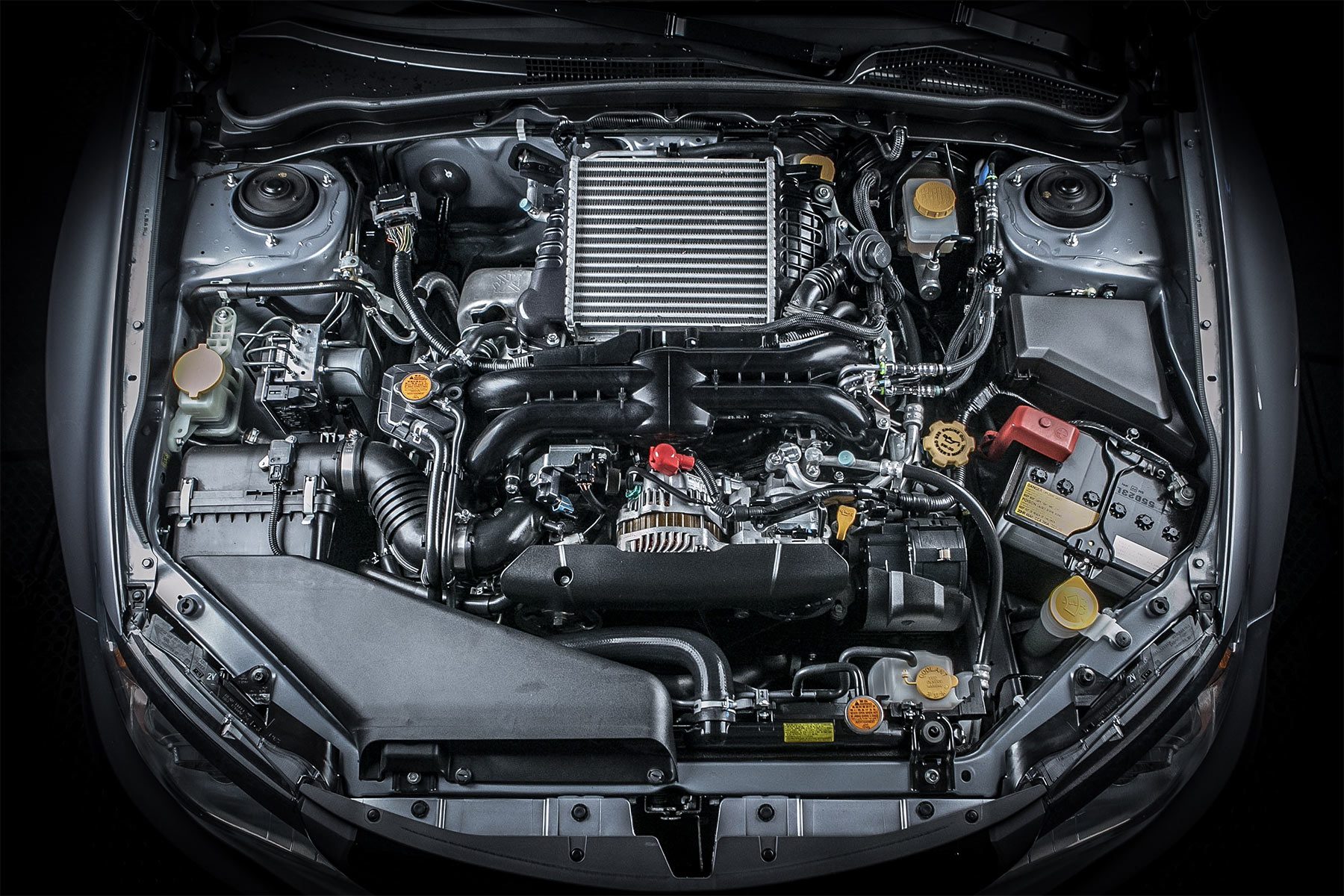

Evolution of Turbocharged Engines

In the automobile industry, the advancement of turbocharged engines has substantially transformed the landscape of performance and efficiency. Turbocharging, as soon as largely seen in high-performance sporting activities vehicles, has now come to be a mainstream innovation taken on by a large range of automobiles, from portable hatchbacks to deluxe cars. The basic concept behind a turbocharged engine is simple yet effective - forcibly even more air into the burning chamber, it permits even more gas to be burned, resulting in boosted power output.

One of the essential benefits of turbocharged engines is their capacity to supply more power from smaller sized, much more fuel-efficient engines. This scaling down trend has actually caused a reduction in exhausts without compromising efficiency, making turbocharging an attractive option for car manufacturers making every effort to fulfill strict ecological regulations. Moreover, turbocharged engines use enhanced torque at lower RPMs, providing motorists with an extra dynamic and receptive driving experience - import engines.

As technology proceeds to development, we can expect additional developments in turbocharging, causing even better degrees of performance and performance in the automotive market.

Innovations in Gas Injection Equipments

With the constant progression of automobile modern technology, substantial improvements have been made in fuel injection systems. Modern fuel injection systems have actually developed to supply gas a lot more efficiently and specifically into the engine cyndrical tubes, boosting total engine performance and gas effectiveness. One of the key advancements in fuel injection systems is the shift from traditional port fuel shot (PFI) to more advanced straight gas injection (DFI) modern technology. DFI systems infuse fuel straight into the combustion chamber at high stress, causing better gas atomization and burning, bring about enhanced power outcome and minimized emissions.

Furthermore, the integration of electronic control devices (ECUs) and sensors in gas shot systems has permitted for real-time changes to fuel distribution based on different aspects such as engine tons, temperature, and driving conditions. Additionally, advancements in fuel injector layout, materials, and spray patterns have actually added to cleaner burning and smoother engine operation.

Combination of Crossbreed Modern Technology

The advancement of fuel shot systems in the direction of higher efficiency and performance has actually set the phase for the smooth combination of hybrid modern technology into contemporary engines. Hybrid technology integrates the use of typical inner combustion engines with electric propulsion systems, supplying enhanced gas efficiency and reduced discharges. By integrating electric motors and batteries right into the powertrain, hybrid engines can supplement the interior combustion engine during velocity or low-speed driving, consequently enhancing overall efficiency.

Improved Engine Management Solution

What are the key improvements in engine monitoring systems that are enhancing the efficiency and effectiveness of modern engines? Engine administration systems have gone through considerable developments to maximize engine performance he said and efficiency. One key technology is the assimilation of innovative sensing units that continuously check various criteria such as engine temperature level, air-fuel proportion, and exhaust discharges. These sensing units provide real-time information to the engine control unit (ECU), enabling for exact modifications to be made to optimize burning processes and gas efficiency.

Additionally, modern-day engine administration systems make use of innovative formulas and fabricated knowledge to examine the information gathered by sensors and make vibrant changes to variables such as ignition timing, gas injection, and turbocharger increase stress. This degree of accuracy and adaptability results in enhanced engine responsiveness, raised power outcome, and decreased fuel consumption.

Additionally, engine management systems now feature innovative analysis capacities that can identify and attend to problems such as misfires, sensing unit breakdowns, and gas system irregularities in real-time, therefore enhancing overall engine reliability and longevity. These developments in engine management systems play a vital role in boosting the driving experience by supplying ideal performance, fuel efficiency, and integrity.

Influence of Lightweight Materials

Incorporating lightweight materials in engine click here to find out more production has changed the automobile industry's method to enhancing fuel effectiveness and performance. Making use of materials such as carbon titanium, light weight aluminum, and fiber has considerably decreased the general weight of engines, causing boosted power-to-weight proportions and enhanced gas economic climate. These light-weight materials offer a higher strength-to-weight proportion compared to standard materials like steel, allowing for greater toughness without endangering performance.

One of the crucial advantages of utilizing lightweight materials in engine building and construction is the reduction of inertia, resulting in quicker engine response times and improved overall vehicle dexterity. Furthermore, the lighter weight adds to reduce power intake, making cars a lot more eco-friendly by decreasing exhausts.

Additionally, the execution of lightweight products in engine elements such as pistons, linking rods, and crankshafts has allowed designers to push the borders of efficiency without giving up dependability (import engines). This innovation has actually led the way for more powerful and efficient engines that supply a remarkable driving experience while satisfying strict emissions criteria

Verdict

In verdict, the current technical innovations in import engines have substantially boosted the driving experience. From the development of turbocharged engines to developments in gas injection systems, integration of crossbreed innovation, improved engine administration systems, and making use of lightweight materials, these technologies have actually collectively enhanced efficiency, gas effectiveness, and total driving dynamics. As technology continues to breakthrough, we can anticipate even much more exciting advancements in the future of import engines.

Modern fuel injection systems have developed to provide gas much more efficiently and exactly into the engine cyndrical tubes, enhancing overall engine performance and fuel effectiveness - import engines. By integrating electric motors and batteries into the powertrain, hybrid engines can supplement the interior combustion engine throughout acceleration or low-speed driving, consequently improving overall performance

What are the essential advancements in engine administration systems that are enhancing the performance and effectiveness of contemporary engines? Engine management systems have actually undertaken substantial developments to optimize engine efficiency and performance. From the development of turbocharged engines to advancements in gas injection systems, assimilation of hybrid innovation, boosted engine management systems, and the use of lightweight products, these innovations have jointly improved performance, gas efficiency, and total driving dynamics.

Report this page